Walking across a carpet, you touch someone or something, and you feel a little “zap”. This little annoyance is far more troublesome to electrical and electronic systems. This common electrical occurrence, can create voltages up to 30,000 volts and lead to major damage if not properly considered. Often times voltages less than 4000 volts can’t even be felt!

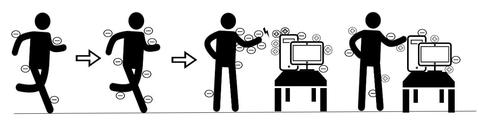

Below you will find a picture of how energy can buildup on person walking across a surface and then discharged a computer. You will notice the buildup and potential difference that exists between the person and the electrical equipment. This real-world example shows the air discharge method, which will be the first method we discuss.

Applications

Taking a look around our daily lives, the role that electronics plays is undeniable. With the proper functioning of these devices impacting our lives, health, and safety reliability is crucial. Common applications include, commercial, military, medical, automotive and many others.

The ongoing emphasis on product reliability has also led to an emphasis on ESD. With the vast number of electrical and electronic devices present in our life, ensuring that products preform in their intended environments is a key factor in customer satisfaction.

Test Methodology & Standards

The two main testing methods are air discharge and contact discharge testing. Air discharge testing involves moving the ESD simulator towards the equipment under test (EUT), whereas, contact discharge, maintains continuous contact.

Often times, standards place preference on the contact discharge testing methods, given the fact it minimizes environmental factors (temperature, humidity, etc.). However, when looking at how electrostatic discharge often occurs, the air discharge methodology is ideal for a field-testing environment.

As mentioned previously, standards are used to verify testing parameters and test levels. The goal of standards is to provide a commonly reproduceable testing criteria. There are a variety of standards that include ESD testing, the most common include EN/IEC 61000-4-2, MIL-STD-883, and ISO 10605. The test setup for EN/IEC 61000-4-2 can be seen below.

Test Equipment

ESD simulators, also known as ESD guns, replicate this type of electrical event. There are variety of manufacturers that provide a diverse set of equipment. The largest and most well-known suppliers include:

- Teseq

- EM Test

- Thermo Fischer Keytek

- EMC Partner

- Noiseken

There are also a variety of accessories that are available for purchase to facilitate testing. These include complete testing setups, discharge tips, and a variety of different testing networks.

Summary

The ability for electronic and electrical equipment and products to be immune, or not to be affected by electrostatic discharge, is often not only advisable but mandatory. Often times discharges can vary in voltages, however the potential impact of these occurrences is an important consideration for electrical and electronic products.

To read more on topics like this, check out the technology category.